Scope of Supply

Northern Light Technologies (NLT) supplied the Codelco Andina project with a personnel mine tracking system that uses RFID technology. In Chile, where the project took place, this system is referred to as a Presence Detection System, and provides real-time tracking information on the location of personnel within the mine. The tracking technology had to be able to read each personnel tag – up to 40 employees per bus entering the mine – travelling at speeds of up to 50 kilometres per hour.

Site Detail

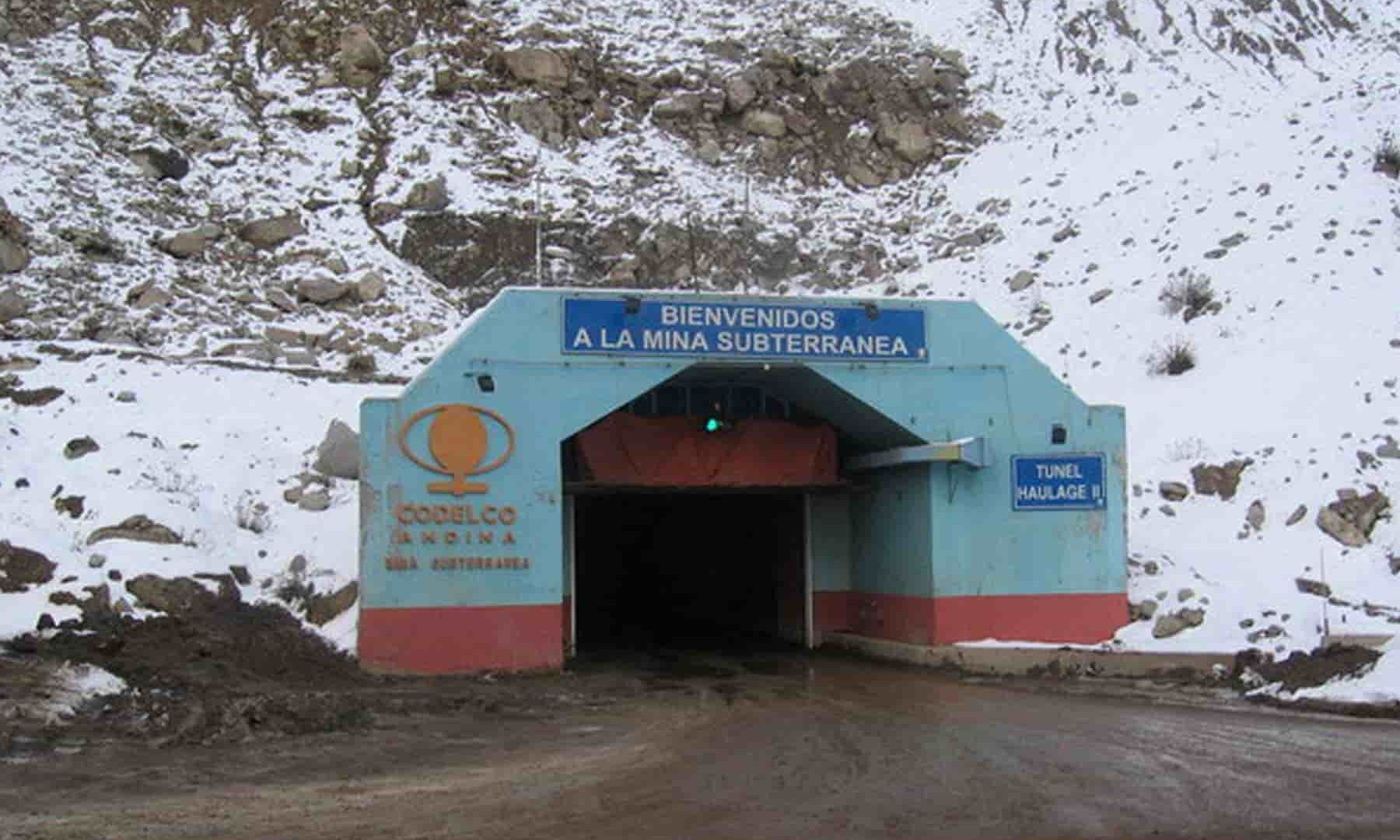

The Codelco Andina mining facilities are located in the fifth region of Los Andes Province in central Chile. Situated at the foot of the Andes Mountains, the mine is stationed at an altitude of between 2,500 and 3,700 meters and is mainly engaged in the extraction of copper and molybdenum concentrate.

Two separate mining areas exist underground in the huge mine and concentrator, with 17 entrances, or ‘portals’. The Codelco Andina shift system currently tracks 2,000 full time employees, as well as up to 9,000 contractors. The workers enter the industrial area by vehicle (truck or bus) and pass check-points (the Control Barrier and the Winter Hut), traveling at 7 kilometres per hour.

The underground mine has five levels with about 100 tunnels; two industrial lifts, five canteens (three inside and two on the surface); 14 admission areas (distributed between the mine and the concentrator); 10 change rooms; and 45 underground offices. The vehicle traffic inside the mine is regulated by automatic traffic light systems that are located throughout every level.

Project Challenges

This project was the first tracking solution of its kind ever implemented – and it just happened to occur in the largest copper mine in Chile, making it essential to select a team of professionals that had experience in sizable mining projects. NLT adapted their current tech and software offering to meet the unique needs of the location, which often involved consulting with other NLT offices across the world. With the majority of staff in Chile speaking Spanish, and Canada and Australia speaking English, a language barrier presented itself.

Fortunately, many of NLT’s employees are fluent in both English and Spanish, so this challenge was easy to mitigate.

The installation of optical fiber across 33 kilometres to cover the entrances, as well as stationary and mobile shelters was critical to the project. It also required the commissioning and installation of 33 communications nodes, eight fiber optic rings, and 79 RFID antennas. Most of the equipment was installed at a height of three metres, with a significant distance between each node.

With four servers, two application servers (for Mine Digital Software), and two database servers, the system needed to be migrated from My-SQL to an SQL Server. NLT also programmed, input, and labelled the data on all employees and contractors for 11,000 tags in their Digital Mine Software. A contents folder system needed to be developed that electronically detailed all the contract information that had previously been physically stored in eight filing cabinets. It also needed to house the detailed information of each installed ring, and two sets of software – a huge undertaking.

Project Details

The purpose of the Presence Detection System was to provide an effective and efficient way of continually controlling the entry, exit, and the location of people in the underground mine, especially in the event of an emergency. The system will eventually be extended to multi-node installations within the mine to more precisely locate the personnel’s whereabouts.

33 km of fiber optics was installed as the transmission medium for the data captured by 79 antennas and RFID readers strategically located at the entrances to the mine, and in mobile and stationary shelters throughout the area. 60% of the fiber was installed into existing small mine conduits; the other 40% of the fiber was carried in the mine’s messenger cabling system. The height of the working sections of the tunnel is about 6 meters, so it was necessary to use a piece of lifting equipment (called a “Manitou”) and all the required personal protective equipment for working at heights.

After the fiber was laid, NLT installed and programmed 33 nodes containing the communication board, consisting of two panels each: one for instrumentation and backup battery, and the second for the fiber optic header. NLT also mounted 79 antennas that connected the nodes and laid the electrical and communications cabling (RS 485). Fiber optic communication and instrumentation cabling was deployed within a galvanized steel conduit to provide the appropriate resiliency and aesthetic within the underground environment. A total of 40 fiber fusion splices were made for optimum network architecture, distributed between 15 horizontal fiber optic spliced enclosures. Each fiber optic ring was certified using the latest generation of instrumentation.

To deliver the most robust solution to the client, the network topology was designed with a fibre optic ring architecture, providing continuity to the network in case of a power short or outage. In total, eight redundant rings were implemented that run throughout all the facilities of Codelco’s Andina division. 10 threads of fibre optic cable were left available for future system expansion.

NLT Chile performed the hiring and accreditation of 80 employees throughout the duration of the project (November 2011 to March 2013), who participated in the various stages of the project in order to complete the final acceptance by the customer.