Tunnel Communication Systems

our work in tunneling tracking and communication systems

NLT is a proud industry expert in the design and installation of flexible communication and tracking systems for the underground tunnelling industry on construction and maintenance projects like roadways, subways, railways, hydro, and service/utility tunnels.

Our engineers will work with you to design a solution that’s based on your individual needs and requirements – we offer the industry’s most reliable and durable communication solutions.

NLT’s goal with any project is to maximize the safety, productivity and profitability of our customers.

our success in tunneling network infrastructure

NLT’s N-Connex product line was made to supply hard rock mines with cost-effective ruggedized network infrastructure. It has provided a network solution that can enable underground IoT around the world in the largest tunneling infrastructure projects in the world. looking for a modular, plug and play solution to reduce downtime and increase safety, security, and productivity.

N-Connex is NLT Digital Solutions’ award-winning rugged, modular, IP67 rated networking solution for harsh environments.

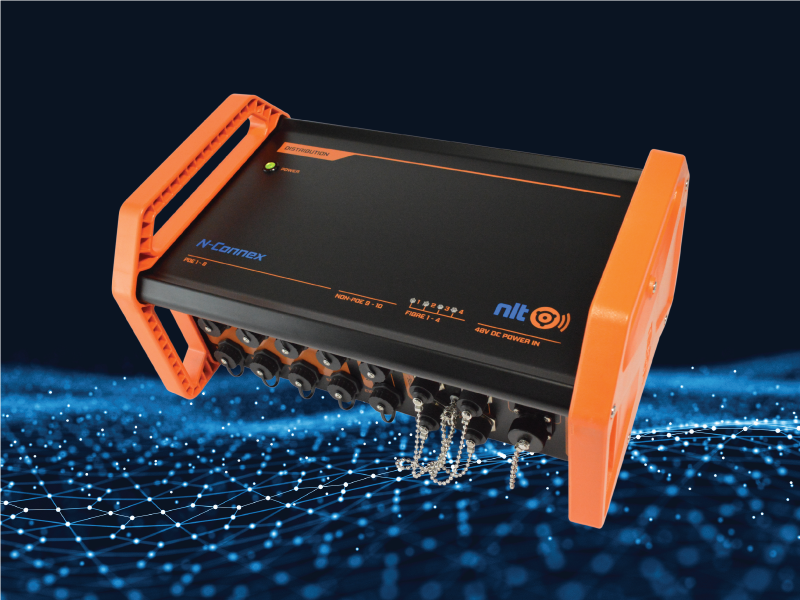

Distribution 2.0 Module

The Distribution 2.0 provides connectivity to a Gigabit Ethernet backbone. The module includes eight (8) managed PoE ports, two (2) Non-PoE Ports and four (4) Single Mode Fibre Ports to enable a range of solutions and network topologies.

The Distribution 2.0 can actively manage 240W (at 25°C) of total Power over Ethernet (PoE) supply across the various Ethernet ports. This enables a large range of high power consuming PoE devices to be simultaneously connected.

When combined with NLT Access Points, we can achieve strong and reliable WiFi coverage in underground mines, tunnels and heavy industrial facilities. NLT’s pre-terminated rugged fibre connects multiple Distribution 2.0’s to form a redundant network topology.

The Distribution 2.0 can easily integrate with SCADA systems, HMI systems and other data acquisition systems. It supports MEF service delivery and timing over packet solutions for IEEE 1588 and synchronous Ethernet. Combined with the small footprint and robust construction, the Distibution 2.0 is ideal for the most critical industrial applications

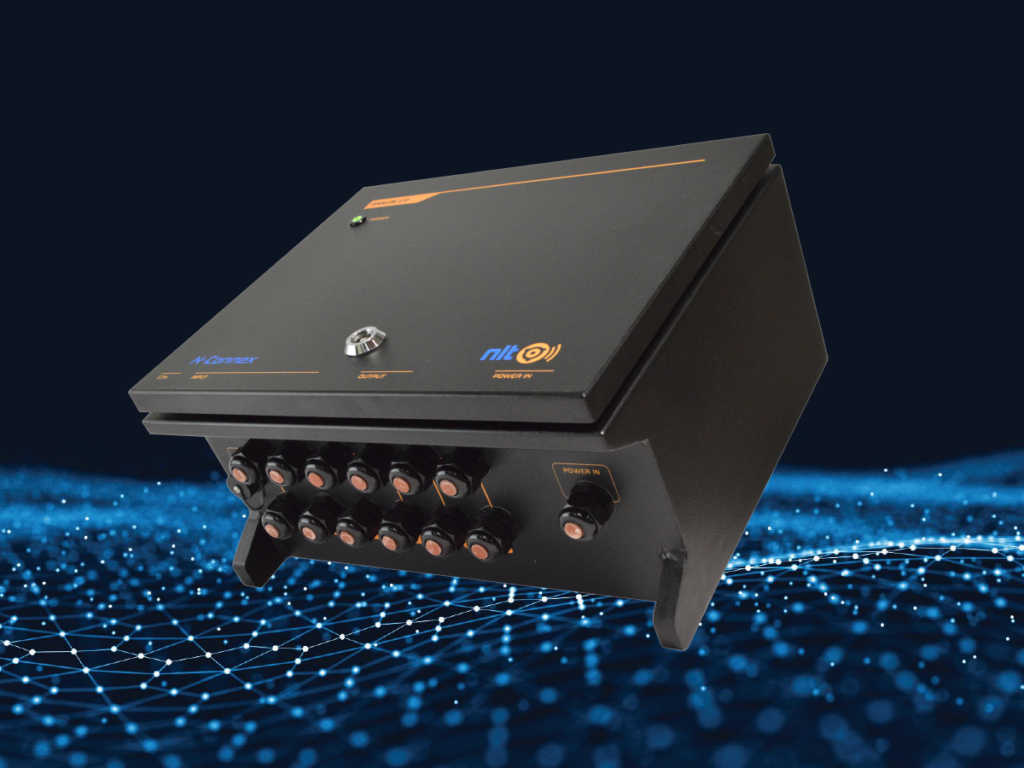

Power 2.0 Module

Adding the optional Battery Module will provide the N-Connex system with an uninterruptible power supply (UPS). The Power Module provides a dedicated connection for the Battery Module. UPS monitoring can be achieved when pairing with a Distribution 2.0.

As with all N-Connex modules the Power 2.0 is rugged and is suitable for harsh environments. The module is designed to be mounted on the NLT quick-fit rail system which can be attached to, or hung from, a variety of surfaces.

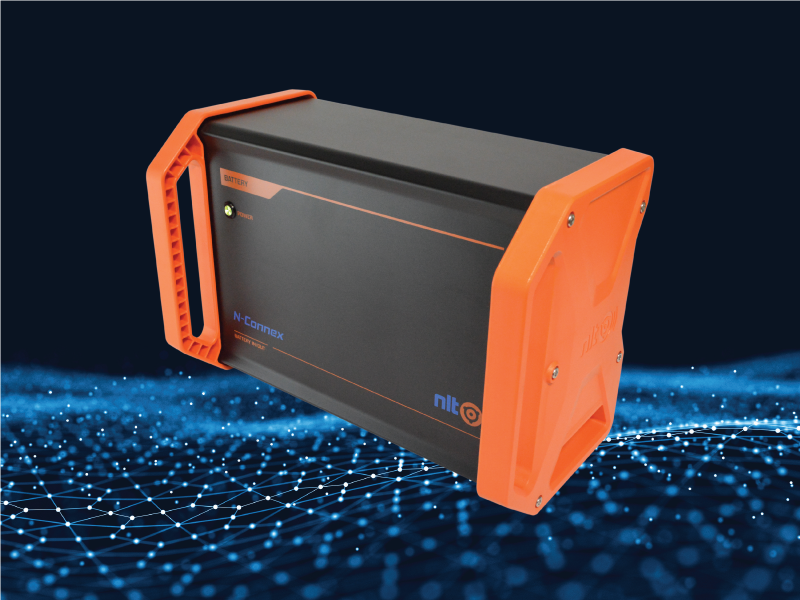

Battery Module

The battery module is designed to provide backup power when the AC power source is shut down. The battery module can connect to the Power Module to provide an uninterruptable power supply (UPS).

It is connected to the Power module with the supplied quick-connect cable, making installation simple and intuitive. The Battery Module will last up to 8 hours or more depending on the N-Connex configuration. A maximum of two Battery Modules can be connected to the Power Module to extend backup time further.

As with all N-Connex modules the Battery Module is rugged and is suitable for harsh environments. The module is designed to be mounted on the NLT quick-fit rail system which can be attached to, or hung from, a variety of surfaces.

Alarm 2.0 Module

Powered by PoE, the Alarm 2.0 is connected to the N-Connex network with a single Cat6 cable making installation simple and intuitive. Paired with N-Connex PoE Extenders, the Alarm Module can be installed up to 300 meters from the Distribution Module.

When placed at key positions the Alarm 2.0 becomes a vital part of the site safety solution. The Emergency Application in NLT’s flagship Digital Mine software can be configured with a map of the site to visualize the state of each alarm. An alarm can be activated locally with the Emergency push button, remotely from Digital Mine software or externally using the supplied digital input

Evacuation 2.0 Module

Powered by PoE, the Evacuation 2.0 is connected to the N-Connex network with a single Cat6 cable making installation simple and intuitive. Paired with N-Connex PoE Extenders, the Evacuation 2.0 can be installed up to 300 meters from a Distribution Module.

When placed at key positions the Evacuation 2.0 becomes a vital part of the site safety solution. The Emergency Application in NLT’s flagship Digital Mine software is used with a map of the site to visualize the state of each alarm. An alarm can be activated locally with the Emergency push button, remotely from Digital Mine software or externally using the supplied digital inputs.

As with all N-Connex modules the Evacuation 2.0 is rugged and is suitable for harsh environments. The module is designed to be mounted on the NLT quick-fit rail system which can be attached to, or hung from, a variety of surfaces.

I/O module

Two versions of the IO module are available: The Analog version and the Digital version. The Analog version is equipped with six (6) analog inputs, two (2) analog outputs , two (2) digital inputs and two (2) digital outputs. The Digital version is equipped with eight (8) digital inputs and eight (8) digital outputs. The digital outputs are driven by relays allowing the use of a wide range of control voltages. The digital inputs are also customizable to a range of control voltages making the IO ideal for almost any control system. .

As with all N-Connex modules the IO Module is rugged and is suitable for harsh environments. The module is designed to be mounted on the NLT quick-fit rail system which can be attached to, or hung from, a variety of surfaces. It can also be mounted separately on its own.

lightning bolt

The Lightning Bolt is a compact dual band outdoor and underground wireless access point. It is equipped with two N-Type antenna connectors to fit an assortment of industry standard antenna options. Powered by gigabit PoE, a single Cat6 cable provides network connectivity and power, making installation easy and intuitive. Additionally, the low power design ensures 802.11AC WiFi can be achieved at up to 300m from the NLT Distribution Module when paired with NLT’s Cat6 extenders.

The secret power of the Lightning Bolt is the built-in WiFi tracking function. When paired with NLT’s Digital Mine software and NLT WiFi tracking tags the Lightning Bolt becomes a powerful tracking device. It is capable of tracking Personnel, Vehicles or Assets that are in the proximity of the Bolt. Location tracking enables you to streamline business processes and improve operations, while also promoting a safer work environment.

Extender

A maximum of 3 Extenders can be used in a daisy chain configuration to extend the connection up to 400 meters, while still providing up to 4 watts of power to PoE peripherals.

When combined with an N-Connex Bolt wireless access point, WiFi coverage can be provided for an entire site.

The Extenders are fitted with IP67 cat6 receptacles to ensure waterproof and dust free connections when using NLT cat6 pre-terminated cables.

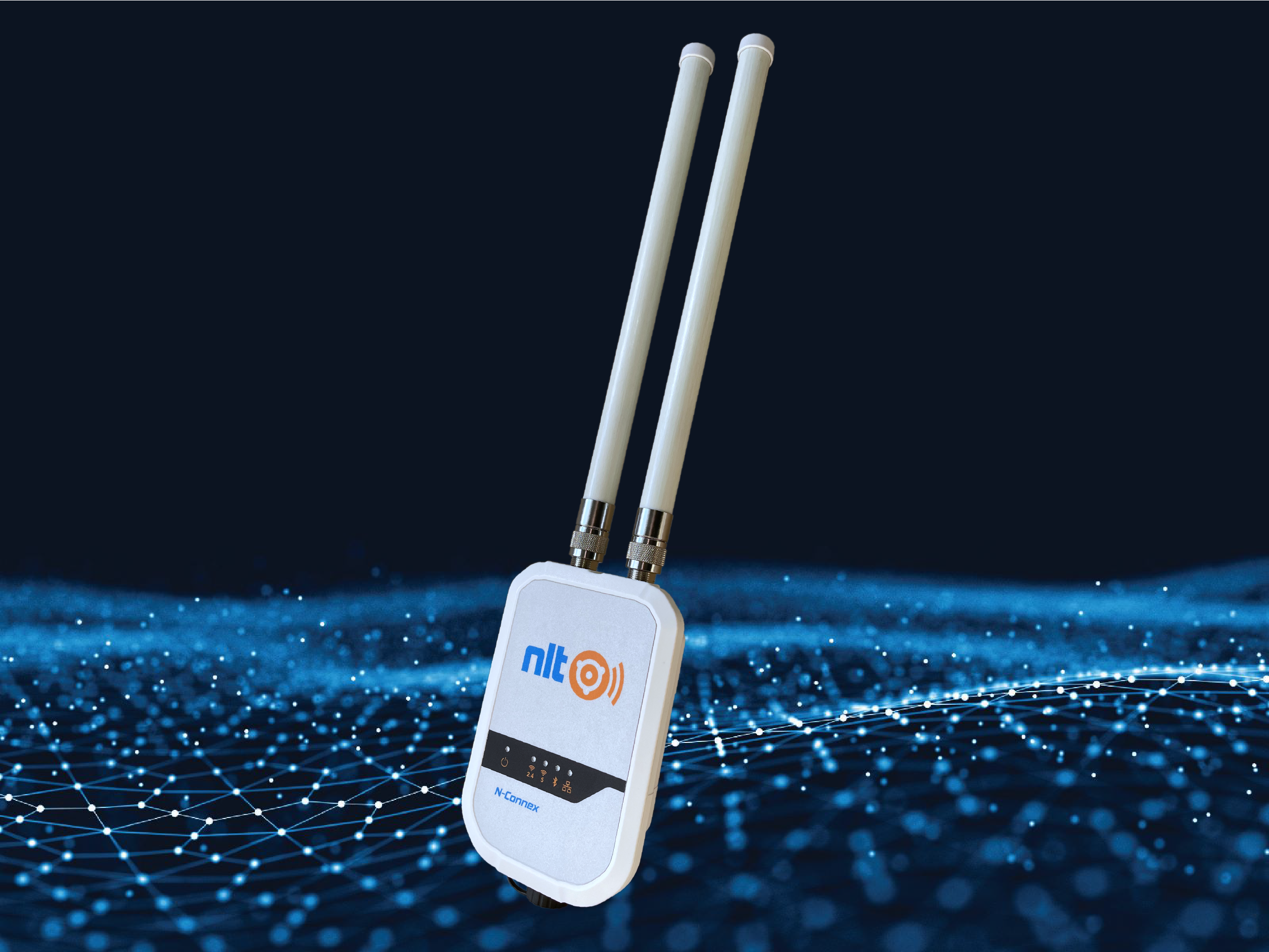

Bolt 2.0

The Bolt 2.0 is a compact 2.4 GHz outdoor and underground wireless access point. It is equipped with an N-Type antenna connector to fit an assortment of industry standard antenna options. Powered by PoE, a single Cat6 cable provides network connectivity and power, making installation easy and intuitive.

The secret power of the N-Connex Bolt 2.0 is the built-in WiFi tracking function. When paired with NLTs flagship software Digital Mine and NLT WiFi tracking tags, the N-Connex Bolt 2.0 becomes a powerful tracking device. It is capable of tracking Personnel, Vehicles or Assets that are in the location of the Bolt.

WiFi Tracking tag

WiFi Tracking Tag messages are received and processed by NLT’s WiFi access points, keeping infrastructure costs low and installation simple. As with all tags, location determination is performed through a unique beaconing method that keeps network impact low and ensures scalability and long battery life.

Wifi Tracking Tags are ideal for personnel tracking and enable you to streamline business processes and improve operations, while also promoting a safer environment.

Communication

Communication is critical for improving safety and maximising development rates. Conversing in real time with underground personnel ensures your operations are running efficiently.

NLT’s range of network-based communication products can be used wherever a WiFi signal is present. This eliminates the need for a separate solution for communication and data networking, improving your overall return on investment. The N-CONNEX network solution is able to provide 100% underground WiFi coverage delivering a seamless Communication Solution when combined with digital WiFi radios and the NLT tracking engine.

Our preferred range of radios from iCOM can be handheld or vehicle mounted. They feature push to talk, individual or group talking and an unlimited number of channels. The Digital iCOM radios feature excellent voice quality and can easily integrate with most telephone networks or other communication platforms.

Smart phones, tablets and any WiFi enabled device can be easily integrated into the NLT network opening avenues of operational management that were previously unknown to the sector.

Installing an N-CONNEX network is the answer to maximise efficiency and productivity.

Keeping track of personnel and critical equipment is essential to maintain safety and enhance productivity. NLT’s integrated Tracking Solution enables an organisation to monitor the location of personnel, vehicles or equipment across your site, wherever the NLT network is installed. The tracking data is forwarded over the network in near real-time, ensuring the tracking information is timely and accurate.

The Tracking System is comprised of:

- Tracking Tags – WiFi or RFID based tags come as a standalone unit or integrated in NLT cap lamps

- Tag Readers – dedicated RFID Tag Reader or integrated into the NLT IS access point

- Digital Mine Software – a Graphical User Interface to view and interpret tracking data

- Tracking Server – the central processing system at the heart of the NLT Tracking Solution

NLT’s Digital Mine suite of software applications is straightforward and offers a range of functionality designed to improve both safety and productivity. The Digital Mine Tracking application enables the geographic location and historic data for an individual, vehicle or asset to be monitored, stored and reported.

The additional benefit of Tracking is achieved easily and cost effectively when an NLT network is installed.

Data Network

The N-CONNEX network provides a high speed Gigabit fibre backbone to handle the most demanding data requirements in a mine. N-CONNEX is standards compliant and will allow any WiFi or Ethernet device to connect and operate over the network.

From laptops and smartphones through to WiFi enabled PLC’s and tags, high speed data communications are made available where you need it most. Mission critical data can be accessed underground in real time. Surveyors can review and update drawings while drill rigs can be uploaded with the latest drill plans. Commonly performed tasks such as accessing emails or vendor websites can also be performed underground when using the N-CONNEX network.

Having secure access to your data servers and the internet can overcome the inherent difficulties in working underground and dramatically improve productivity and safety.

Control And Automation

The N-CONNEX network provides a reliable and robust data highway that enables simple telemetry and automation of equipment. Monitoring and controlling electrical equipment such as fans or pumps results in considerable cost savings and improved efficiency. Additionally, automating equipment saves time, improves safety, and enhances productivity.

Automation can include the automatic starting and stopping of equipment like feeder breakers or conveyors through to supporting complex automated vehicles. The high speed data backbone of the N-CONNEX network, combined with our WiFi access points, provide the infrastructure to support the most complex automation tasks. Whether using simple digital on/off signals or complex analog measurements, the data is easily transferred to our Digital Mine Software, or a SCADA package of your choice, for manipulation, display and control.

Integrating NLT’s range of solutions including Tracking, Video Monitoring, Communication and Software Applications further enables the automation and reporting capability to increase productivity, efficiency and safety.

Monitoring environmental conditions is critical to making informed safety and production decisions for your operation.

NLT partners with leading-edge providers of Environmental, Ventilation, Gas, and Geotechnical Monitoring Systems to provide solutions that are reliable and accurate, enhancing operational efficiency and safety. From local design and manufacture to distribution and support, NLT works with our customers and technology partners to ensure you have access to the very best monitoring technologies.

Integrating these systems with the NLT networking infrastructure enables real-time monitoring and data capture. This critical data can be used to automate production and safety processes. Historical data can be analysed to fully understand the conditions in your operation.

We’re integration experts – providing complete solutions to monitor critical conditions vital to your operation. We can connect any monitoring system to your existing monitoring and control software systems, or through the NLT Digital Mine software, giving you access to valuable and relevant data at your fingertips.

NLT offers a full range of condition monitoring systems and solutions:

- Ultrasonic Ventilation Airflow Monitoring – highly accurate airflow and quality measurements

- Environmental Monitoring – temperature, humidity, pressure, wet bulb, dry bulb, heat stress index, and more

- Geotechnical Monitoring – subsidence monitoring,slope/high wall monitoring detects the most minute ground movement

- Gas Monitoring – toxic and combustible gases, oxygen and inert gases

- Software, Integration and Networking – Digital Mine suite of software, SCADA/PLC systems

NLT has designed and built several vehicle management systems to meet a variety of customer needs.

Our latest project is for vehicle warning and shut down when entering a no-go zone. When a vehicle approaches a no-go zone within a defined distance, a Warning strobe and beacon is activated. If the vehicle continues into the no-go zone, an Alarm strobe is activated and the vehicle is shut down. The vehicle is not able to be restarted until it is outside the no-go zone and a keyed override is activated.

There are an infinite number of safety and operational improvements that can be implemented when combining NLT’s Tracking engine, an NLT network and a little bit of ingenuity. Contact NLT for your next Vehicle Management project.

Ventilation On Demand

The NLT VOD Solution enables a mine to ventilate zones based on real time environmental parameters and tracking information. Utilising the Digital Mine suite of software combined with a Tracking enabled NLT network, VOD can ensure ventilation is operating efficiently where and when it is needed. This leads to significant cost savings based on energy reduction as ventilation draws significant power and energy.

The VOD solution combines a number of NLT and partner products including air-flow monitoring, tracking data, N-Connex Control modules and the Digital Mine Suite of software. When this data is combined, zone parameters can be defined and automation of the Ventilation system to be achieved.

Software & Applications

NLT’s Digital Mine Software is a web-based package that provides controlled access to real time critical data. The user interface while being simple to use and intuitive provides in-depth information that ensures tunnelling operations are conducted safely and efficiently. The data is overlaid on your actual tunnel plans so a user can quickly assess the situation and understand any implications implied by the data. Reporting is comprehensive and easily navigated as well as providing the support for customised templates to be created.

Digital Mine Software also integrates with third party hardware and software to provide increased functionality. Equipment status and system health are easily viewed, while personnel information can be interfaced with other systems, including card access. Any vehicle or tag movement patterns can be monitored, ensuring both the safety and efficiency of your equipment operators.

Some of the innovative features, include:

- Multi-level Map Interface, overhauled with an easy to use Google Maps style overview to track or locate anything, including environmental monitoring points.

- Zone Management – quickly establish zones that cover specific sections of the tunnel(s) to enhance the capabilities of Tracking or Alarm functions.

- Monitor and control equipment based on real time condition monitoring such as fans or pumps.

- Emergency alarm and response management.

Digital Mine will increase efficiencies and productivity of your workforce while also significantly enhancing the overall safety systems.

Northern Light Technologies is a proud producer of advanced safety and productivity technologies for underground mining, tunneling, and heavy industry. Since 1984, our high-quality cap lamps have been engineered to provide workers with the best lighting and safety in the harshest environments.

We offer products for unique mining needs, from MSHA and IECEx approved all-in-ones to proximity warning and wifi-tracking cap lamps.

Visit NLT Cap Lamps for more information.